Amazon.com: Fever-Tree Refreshingly Light Tonic Water, 16.9 Fl Oz (Pack of 5) : Grocery & Gourmet Food

Amazon.com : Fever-Tree Refreshingly Tonic Water, Light, 16.9 Fl Oz (Pack of 8) : Soda Soft Drinks : Grocery & Gourmet Food

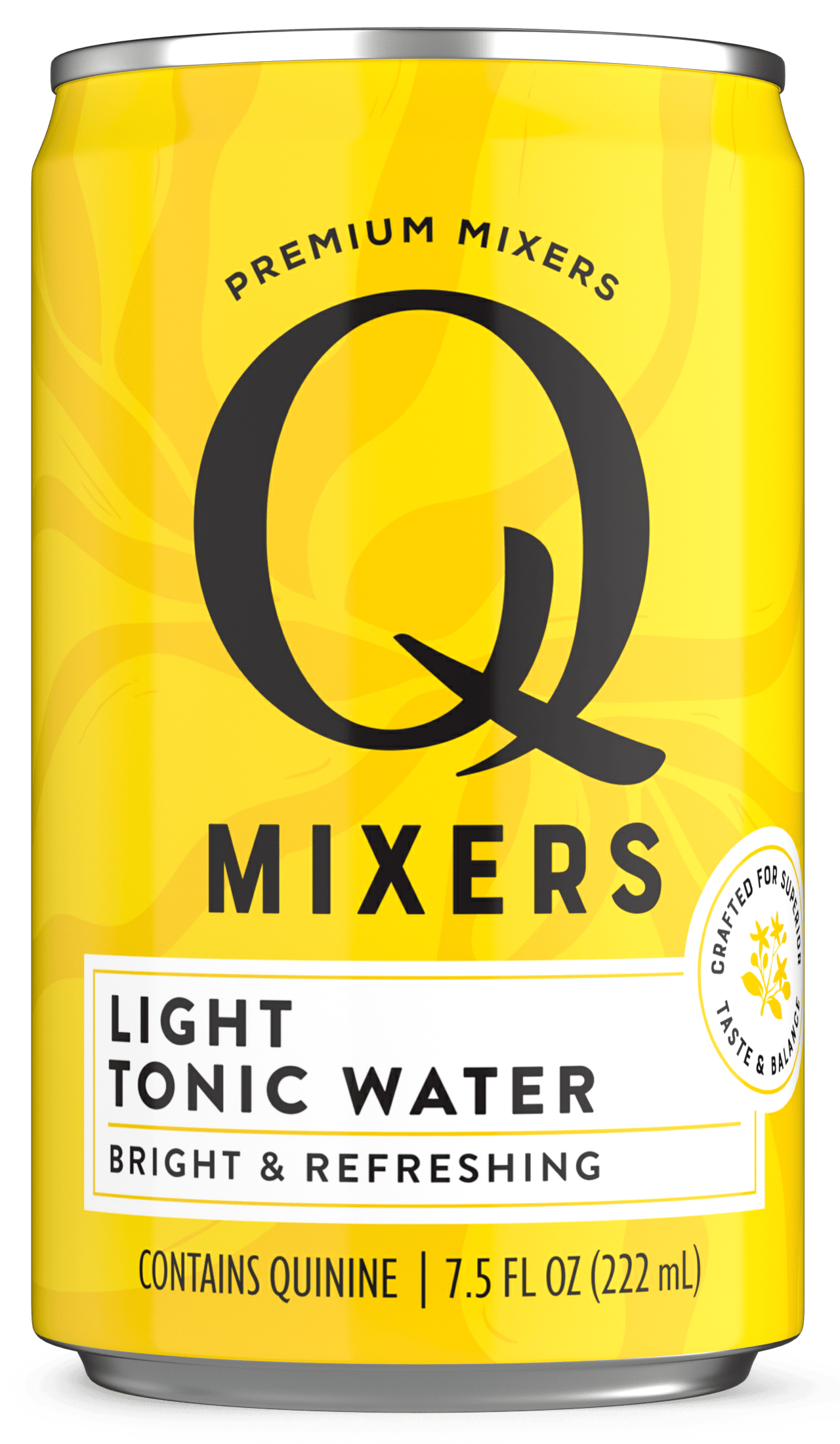

Q Mixers Light Tonic Water, Premium Cocktail Mixer Made with Real Ingredients, 7.5 fl oz (pack of 4) - Kroger