Ariana Grande Lands Her Biggest YouTube Debut Yet With 'No Tears Left to Cry' | Billboard – Billboard

Ariana Grande Performs 'No Tears Left to Cry' Live on TV for First Time! (Video): Photo 4075602 | Ariana Grande, Music Pictures | Just Jared

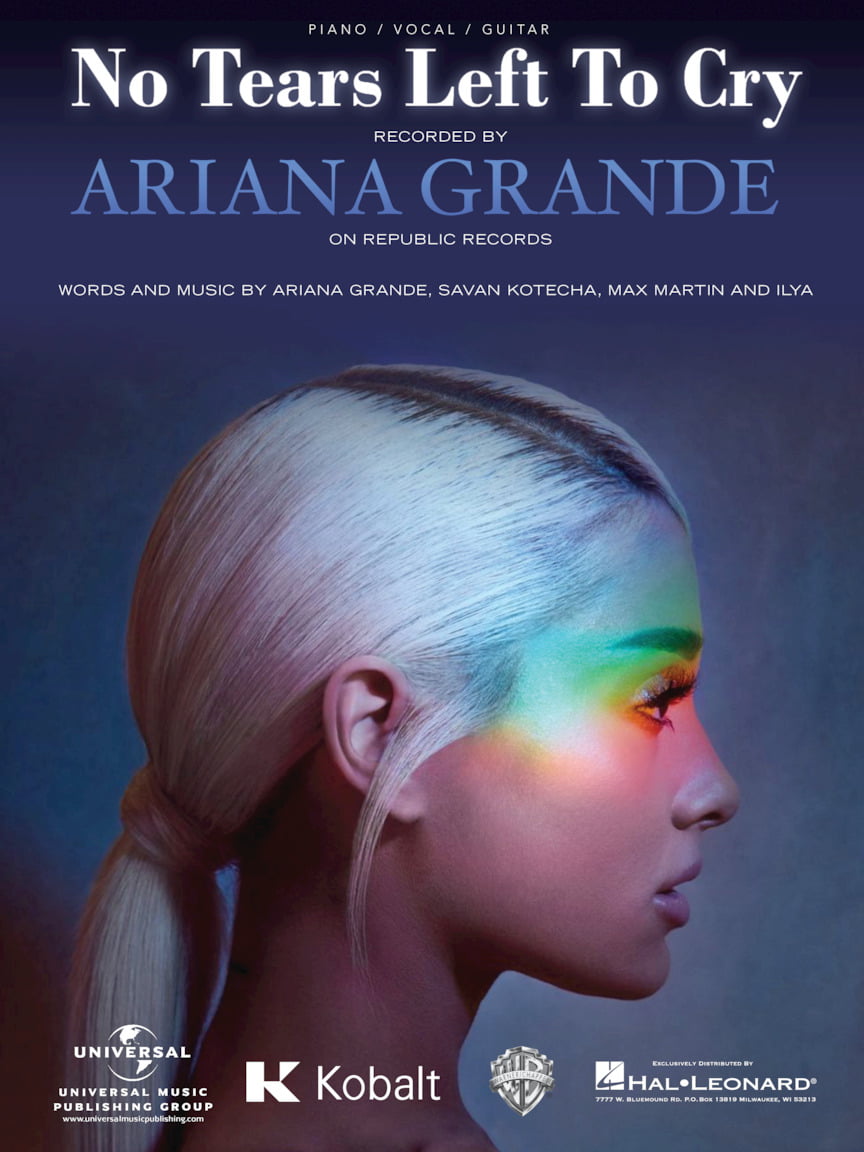

Ariana Grande "No Tears Left To Cry" Sheet Music PDF Notes, Chords | Pop Score Guitar Ensemble Download Printable. SKU: 419196

![Ariana Grande - No Tears Left To Cry (feat. Nicki Minaj) (Audio) [Mashup] - YouTube Ariana Grande - No Tears Left To Cry (feat. Nicki Minaj) (Audio) [Mashup] - YouTube](https://i.ytimg.com/vi/TkdcEHM3arU/hqdefault.jpg)